Contents

- 1 TL;DR

- 2 Predictive Data Analytics in Supply Chain

- 2.1 Understanding Predictive Analytics in Supply Chain Management

- 2.2 How Predictive Analytics Works

- 2.3 Predictive Analytics vs Other Types of Analytics

- 2.4 How Do Organizations Use Predictive Analytics?

- 2.5 Statistical Algorithms and Machine Learning Models often Used

- 2.6 Challenges Organizations Face When Implementing Predictive Analytics

- 3 Best Tools for Predictive Analytics in Supply Chain

- 4 Future Trends

TL;DR

- Predictive data analytics transforms supply chain management by forecasting future events, optimizing operations, and aiding strategic decision-making.

- It employs historical data, statistical algorithms, and machine learning models to predict future demand, logistics, and risk management outcomes.

- Organizations use predictive analytics for demand prediction, production scheduling, inventory optimization, predictive maintenance, fleet and route planning, cost and pricing optimization, supply chain risk management, and enhancing the customer experience.

- Implementing predictive analytics can pose challenges, including data quality and availability, change management, and integration with existing systems.

- The future will likely show increased use of AI and machine learning, real-time analytics, more integration across the supply chain, prescriptive analytics, and an intense focus on data privacy and security.

Predictive Data Analytics in Supply Chain

In supply chain management, predictive data analytics has emerged as a game-changer. Predictive analytics puts some numbers behind management intuition and experience, allowing businesses to anticipate future events, optimize operations, and make strategic decisions that drive growth and profitability.

Understanding Predictive Analytics in Supply Chain Management

Predictive analytics in the supply chain involves using data, statistical algorithms, and machine learning techniques to identify the likelihood of future outcomes based on historical data. It’s all about providing the best assessment of what will happen, so businesses can feel more confident about making proactive decisions and preparing for what’s ahead. These assessments could involve predicting product demand, anticipating logistical challenges, or identifying potential risks in the supply chain.

How Predictive Analytics Works

Predictive analytics involves several steps. First, it requires a dataset of historical information. This data is then cleaned and prepared for analysis. Next, statistical algorithms and machine learning models are applied to the data to identify patterns and trends. Supply chain professionals can use these patterns to make predictions about future events. Professionals must remember that these predictions are not written in stone and must be considered as part of the broader context. Professionals will likely use their qualitative industry experience to come to a final decision on topics.

Predictive Analytics vs Other Types of Analytics

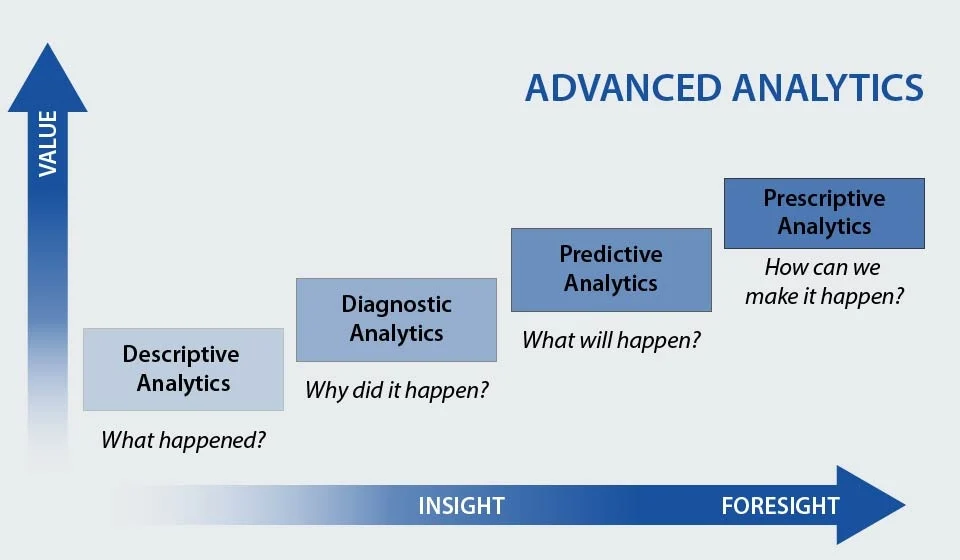

While predictive analytics focuses on forecasting future events, it’s just one type of analytics used in supply chain management. Descriptive analytics, for example, focuses on analyzing historical data to understand what has happened in the past. Diagnostic analytics goes further, analyzing data to understand why certain events occurred. Finally, prescriptive analytics uses data to recommend actions to achieve desired outcomes. Each type of analytics plays a unique role in helping businesses manage their supply chains more effectively.

How Do Organizations Use Predictive Analytics?

Predictive analytics has become a vital tool for organizations across various industries. By leveraging data and machine learning, predictive analytics allows businesses to anticipate future trends, optimize operations, and make strategic decisions. Here are some of the critical ways organizations use predictive analytics:

- Demand Prediction: Predictive analytics can analyze historical sales data and market trends to predict future demand for products or services. This allows businesses to better plan their production and inventory, reducing the risk of stockouts or overstocking.

- Production Scheduling: By predicting demand, predictive analytics can also help businesses optimize their production schedules. When product demand is more accurately forecasted, production planners can plan their production runs more accurately, minimizing disrupted priority changes. This has the effect of improving product line utilization and the COGS for that product.

- Inventory Optimization: Predictive Analytics can help businesses optimize their inventory levels, ensuring they have the right amount of stock at the right time. This can reduce storage costs, minimize waste, and improve cash flow.

- Predictive Maintenance: Predictive Analytics can analyze data from equipment and machinery to predict better when they need maintenance or repairs. This can help businesses avoid costly downtime and extend the lifespan of their equipment.

- Predictive Fleet and Route Planning: For businesses with fleets of vehicles, predictive analytics can optimize route planning, considering factors like traffic, weather, and fuel costs. The expectations set by the company often drive customer satisfaction; if they can better predict how long delivery will take or even shorten the delivery time, customer service will be improved, yielding sales growth.

Statistical Algorithms and Machine Learning Models often Used

Predictive analytics in supply chain management often leverages various statistical algorithms and machine learning models to analyze data and make predictions. The idea is not to provide a comprehensive guide but rather a taste of some models. Here are some of the most commonly used ones:

- Linear Regression: An essential and commonly used statistical technique that predicts a response variable by fitting a linear equation to observed data. In supply chain management, Linear Regression can predict continuous outcomes such as future sales or demand based on historical data.

- Time Series Analysis involves analyzing historical data collected to identify trends, cycles, and seasonal variations. This can be particularly useful for forecasting demand or sales in supply chain management.

- Decision Trees and Random Forests: These machine-learning models can handle categorical and numerical data. They are beneficial for classification problems, such as predicting whether a supplier will default or not.

- Neural Networks: These are complex machine learning models that are particularly good at identifying patterns and trends in large datasets. They can be used for various predictive analytics tasks in supply chain management, from demand forecasting to inventory optimization. Neural networks are often considered the most potent ML algorithm out there but are not without drawbacks; usually, it’s computationally taxing, requiring distributed computing.

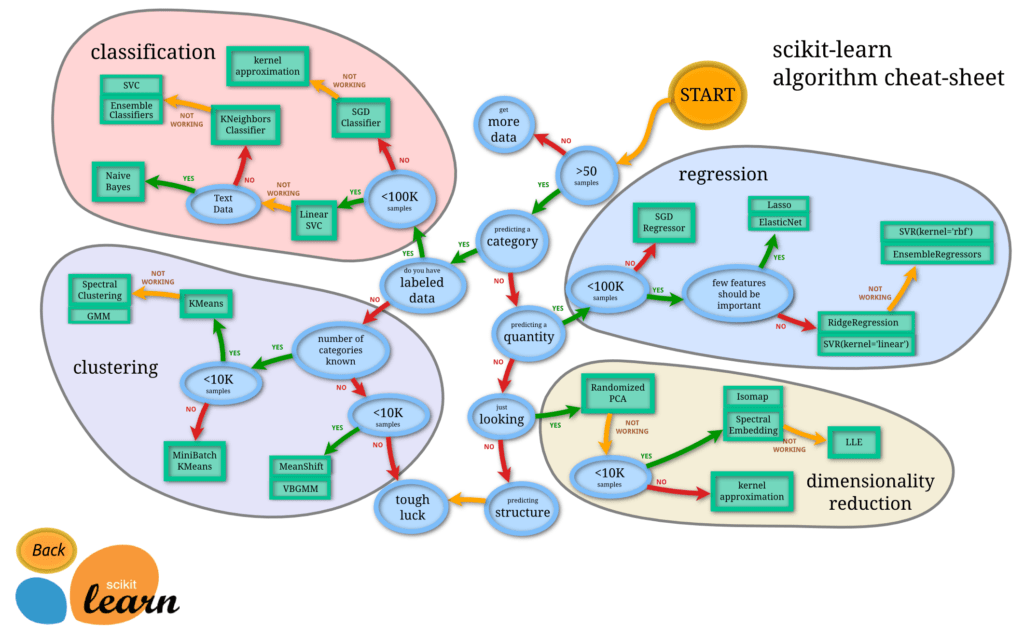

Remember, there is no one size fits all approach, and your choice of algorithm depends on many factors. The selection of an algorithm is such a critical strategic choice that many companies implement an ensemble solution using the average of the predictions made by many of the algorithms mentioned above. As a starter, the popular package scikit-learn for Python has many of the above capabilities and a handy cheat sheet. See below:

Challenges Organizations Face When Implementing Predictive Analytics

While predictive analytics offers numerous benefits, implementing it has its challenges. Organizations often encounter several obstacles when trying to leverage predictive analytics, and here are some of the most common ones:

Data Quality and Availability

Predictive analytics relies heavily on data. However, many organizations need help accessing high-quality, relevant data. Often, the data is inaccessible, inaccurate, or outdated, which can significantly impact the effectiveness of predictive analytics. Additionally, data may be spread across different systems or departments, making it difficult to collect and analyze. Therefore, ensuring data quality and availability is a significant challenge when implementing predictive analytics.

Change Management

Implementing predictive analytics requires significant changes to an organization’s processes and culture. Employees may need to learn new skills or adapt to new working methods, which can be challenging. Additionally, there may be resistance to change, mainly if the benefits of predictive analytics have yet to be clearly articulated. Therefore, Effective change management is crucial for successfully implementing predictive analytics.

Integration with Existing Systems

Predictive analytics is not implemented in isolation and must be integrated with an organization’s existing systems, such as its CRM or ERP system. This can be technically complex and time-consuming. Additionally, if the existing systems need to be updated or designed to support predictive analytics, this can pose further challenges. Organizations, therefore, need to carefully plan and manage the integration process to ensure the successful implementation of predictive analytics.

Best Tools for Predictive Analytics in Supply Chain

There are several tools available that can help organizations leverage predictive analytics in their supply chain. Here are some of the best ones:

Anaconda is a well-known open-source platform often used in research or education that supports data science and machine learning. It provides various tools for data preprocessing, analysis, and model deployment.

Anaconda is best for organizations with in-house data science capabilities and prefers to use Python or R for their predictive analytics tasks.

Alteryx is a data analytics platform that provides various tools for data preparation, blending, and analytics. It also offers advanced predictive analytics capabilities.

Alteryx is best for organizations that want a user-friendly, drag-and-drop interface for their predictive analytics tasks and must blend data from various sources.

SAP Analytics Cloud is a business intelligence and predictive analytics platform. It provides tools for data visualization, planning, and predictive modelling.

SAP Analytics Cloud is best for organizations already using SAP’s other software solutions or those needing a robust, enterprise-grade predictive analytics solution.

DataRobot is an automated machine-learning platform. It automates many tasks in developing predictive models, making it easier for non-experts to leverage machine learning.

DataRobot is best for organizations wanting to leverage machine learning for predictive analytics but needing more in-house expertise.

H2O.ai provides an open-source machine-learning platform that supports a range of machine-learning algorithms. It also offers an automated machine learning platform called H2O Driverless AI.

H2O.ai is best for organizations with in-house data science capabilities who want to leverage machine learning for predictive analytics.

Tableau is a data visualization tool that also provides some predictive analytics capabilities. It allows users to explore data visually and identify trends and patterns.

Tableau is best for organizations that want a user-friendly data exploration and visualization tool and need only basic predictive analytics capabilities.

The Best Solution for You Depends on Many Factors

While these tools offer potent capabilities, it’s important to remember that the best tool for your organization will depend on your specific needs and circumstances. Factors that companies must consider may include the complexity of your data, the skills and expertise of your team, and your budget. It’s also important to remember that predictive analytics should not be used in isolation but as part of a broader corporate strategy.

Future Trends

As technology continues to evolve, so too does the field of predictive analytics. Here are some of the key trends that are expected to shape the future of predictive analytics in supply chain management:

Increased Use of Artificial Intelligence and Machine Learning

We will see AI and machine learning used in predictive analytics more and more. These technologies can analyze vast amounts of data more quickly and accurately than humans, making them invaluable for demand forecasting and risk assessment tasks. As AI and ML technologies continue to improve, we can expect them to play an even more prominent role in predictive analytics.

Real-Time Analytics

Would you be confident in making a crucial decision with month-old data? Likely not. As we can access more data and better tech solutions, there is a growing demand for real-time analytics. This involves analyzing data as soon as it is available, allowing businesses to make immediate decisions. This can be particularly valuable in the supply chain, where conditions change rapidly.

Integration of Predictive Analytics Across the Supply Chain

While many businesses currently use predictive analytics in specific areas of their supply chain, there is a growing trend towards integrating it across the entire supply chain. This can provide a more holistic view of the supply chain, helping businesses to make more informed decisions.

Prescriptive Analytics

Prescriptive analytics goes a step beyond predictive analytics, using data not just to predict future events but also to recommend actions that can lead to desired outcomes. Many companies are implementing scenario analysis as the basis for prescriptive analytics, and I expect to see more companies start to explore the possibilities of prescriptive analytics.

Increased Focus on Data Privacy and Security

As businesses collect and analyze more data, there is growing concern about data privacy and security. Companies must comply with data protection regulations and protect their data from cyber threats. This will likely be a key focus area for businesses using predictive analytics in the future.