Contents

- 1 Introduction

- 2 What are “Master Data-Driven Strategic Insights”

- 3 The Importance of Data-Driven Strategic Insights

- 4 Key Components of Data-Driven Decision Making

- 5 Reactive vs. Proactive Problem Solving: Pros and Cons

- 6 Finding the Balance between Reactive and Proactive Problem Solving

- 7 Building a Data-Driven Culture

- 8 Implementing Data-Driven Strategies in Supply Chain and Manufacturing

- 9 Conclusion

Introduction

In today’s fast-paced business environment, companies in the supply chain and manufacturing domains need to stay ahead of the competition by making informed and timely decisions. To achieve this, organizations must harness the power of data-driven strategic insights. By leveraging advanced analytics and data visualization techniques, businesses can unlock hidden opportunities, optimize processes, and make more effective decisions. This blog post will guide you through master data-driven strategic insights to help you unlock success in your supply chain and manufacturing operations.

What are “Master Data-Driven Strategic Insights”

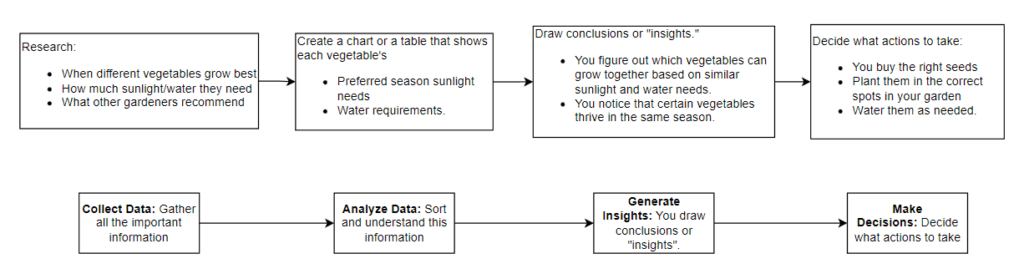

Understanding corporate terminology can sometime be difficult, so lets use a more concrete example. Imagine you’re trying to grow a successful vegetable garden. How would you approach this?

- Collect Data: To start with, you gather all necessary information. You research when different vegetables grow best, how much sunlight and water they need, and what other gardeners recommend. This is similar to collecting data in a business context.

- Analyze Data: Next, you sort and understand this information. You might create a chart or a table that shows each vegetable, its preferred season, sunlight needs, and water requirements. This process is like data analysis – organizing and making sense of raw data.

- Generate Insights: Now, based on your organized data, you draw conclusions or “insights.” You figure out which vegetables can grow together based on similar sunlight and water needs. You notice that certain vegetables thrive in the same season. These insights aren’t directly given in your data, but you understand them by examining your organized data.

- Make Decisions: Finally, you take these insights and use them to decide what actions to take. You buy the right seeds, plant them in the correct spots in your garden, and water them as needed. In business, this would be akin to making strategic decisions based on the insights gained from your data.

So, Data-Driven Strategic Insights are about using information to create a thriving garden (or business). It involves collecting information, organizing and understanding it, deriving meaningful insights, and using those insights to make informed decisions.

The Importance of Data-Driven Strategic Insights

Data-driven strategic insights enable businesses to make informed decisions by uncovering hidden patterns, trends, and correlations within their data. This empowers supply chain and manufacturing organizations to identify opportunities for cost reduction, streamline processes, improve customer satisfaction, and ultimately, increase profitability. By adopting a data-driven approach, companies can stay agile and responsive in the face of rapidly changing market conditions and customer demands.

The cost of not using Data-Driven Strategic Insights

Failing to proactively seek data-driven insights can have significant costs for any business, particularly those in the supply chain and manufacturing industries. Without these insights, decision-making becomes largely reactive and based on gut feelings or outdated methods, rather than on concrete data. This can lead to missed opportunities, inefficient processes, and ultimately, lower profitability.

For instance, without analyzing sales data and market trends, a manufacturing company may not foresee a decrease in demand for a particular product, resulting in overproduction and excess inventory costs. Similarly, a supply chain company might miss out on optimizing their logistics network, leading to higher transportation costs and longer delivery times.

Therefore, embracing a proactive approach to generating and utilizing data-driven insights is not just a nice-to-have, but an essential part of modern business strategy. It enables businesses to anticipate changes, optimize operations, and make strategic decisions that drive growth and success.

Key Components of Data-Driven Decision Making

To master data-driven strategic insights, organizations must understand the key components involved in data-driven decision making:

- Data Collection and Management: Effective data-driven decision making begins with collecting and managing high-quality data from various sources, such as sensors, IoT devices, and enterprise systems. Implementing a robust data management strategy ensures that your data remains accurate, consistent, and up-to-date, providing a solid foundation for analysis.

- Data Analysis Techniques: Applying the right data analysis techniques can help uncover valuable insights from your data. Techniques such as descriptive, diagnostic, predictive, and prescriptive analytics can provide insights into what happened, why it happened, what might happen, and what actions to take, respectively.

- Data Visualization and Reporting: Visualizing data through graphs, charts, and dashboards makes it easier for decision-makers to comprehend complex information and identify patterns or trends. Effective data visualization and reporting tools enable stakeholders to quickly grasp key insights and make informed decisions.

More information can be found here from mckinsey.com

Reactive vs. Proactive Problem Solving: Pros and Cons

In the context of supply chain and manufacturing operations, problem-solving approaches can be broadly classified into two categories: reactive and proactive. Understanding the pros and cons of each approach is crucial for determining the best strategy for your organization.

Reactive Problem Solving

Reactive problem solving involves addressing issues as they arise, often focusing on immediate solutions to mitigate the impact of the problem. This approach is generally more short-term and tends to prioritize visible problems.

| Pros | Cons |

|---|---|

| Quick response: Reactive problem solving enables organizations to address issues immediately, potentially minimizing their impact on operations. | Short-term focus: Reactive problem solving may lead to short-term solutions that don’t address the root cause of the issue, resulting in recurring problems. |

| Simple implementation: This approach often requires less planning and resources, making it easier to implement in certain situations. | Limited visibility: Focusing on immediate issues may cause organizations to overlook less obvious but high-impact problems that could have a significant long-term impact on their operations. |

Proactive Problem Solving

Proactive problem solving involves identifying potential issues before they become significant problems and taking action to prevent or mitigate them. This approach leverages data-driven strategic insights to uncover hidden opportunities and challenges, enabling organizations to make more informed decisions.

| Pros | Cons |

|---|---|

| Long-term focus: Proactive problem solving addresses the root cause of issues, leading to long-term solutions that improve overall operations. | Requires investment: Proactive problem solving often requires investment in data management, analytics tools, and employee training, which may be a barrier for some organizations. |

| Anticipation of potential problems: By identifying potential issues before they escalate, organizations can reduce the risk of costly disruptions and maintain a competitive edge. | Complexity: The proactive approach can be more complex than reactive problem solving, as it involves analyzing large volumes of data and requires a deep understanding of the underlying processes. |

| Continuous improvement: This approach encourages organizations to constantly evaluate their processes and performance, fostering a culture of continuous improvement. | |

| Resource optimization: Proactive problem solving allows for better allocation of resources, as organizations can prioritize high-impact initiatives and allocate resources more effectively. |

Finding the Balance between Reactive and Proactive Problem Solving

While both reactive and proactive problem-solving approaches have their advantages and disadvantages, finding the right balance between the two is crucial for supply chain and manufacturing organizations to optimize their operations effectively. Leveraging data-driven strategic insights can play a key role in striking this balance, as it provides increased visibility into your operations and helps inform decision-making.

5 steps to find balance between reactive and proactive problem solving

Here are some steps to help find the balance between reactive and proactive problem solving:

- Prioritize issues based on impact: Use data-driven insights to identify high-impact issues, both immediate and potential, and prioritize them accordingly. This will ensure that resources are allocated to address urgent problems while also investing in proactive measures to prevent or mitigate future issues.

- Develop a data-driven mindset: Encourage employees to adopt a data-driven mindset, using data to inform both reactive and proactive decision-making. Fostering a data-driven culture will enable your organization to respond effectively to immediate problems while also planning for long-term success.

- Invest in analytics tools and technologies: Implement advanced analytics tools that can help uncover hidden insights within your data, allowing for both proactive problem identification and more effective reactive problem-solving. These tools can also help identify patterns and trends that may indicate underlying issues that require a proactive approach.

- Continuous monitoring and improvement: Regularly review and analyze your operations to ensure that proactive measures are working as intended and to identify areas where reactive problem-solving may be necessary. Establishing a continuous improvement process will enable your organization to respond to immediate issues while constantly refining and optimizing your proactive strategies

- Collaboration and knowledge sharing: Encourage cross-functional collaboration and knowledge sharing among teams, as this can help identify potential problems before they escalate and enable more effective reactive problem-solving when necessary. Collaboration can lead to a more holistic view of your operations, allowing for better decision-making and balancing between reactive and proactive approaches.

Building a Data-Driven Culture

Building a data-driven culture is a fundamental step in mastering data-driven strategic insights. To foster this culture within your organization, consider the following strategies:

- Encourage curiosity and critical thinking: Empower your employees to question existing practices and seek innovative solutions. Encourage them to use data in their decision-making process.

- Provide adequate training: Equip your employees with the necessary skills to interpret and utilize data effectively. This includes training on data management, analytics tools, and decision-making techniques.

- Promote transparency and open communication: Share data insights across the organization and involve all employees in decision-making processes. This will foster a sense of ownership and commitment towards achieving the organization’s goals.

- Recognize and reward data-driven decision making: Acknowledge and reward teams and individuals who successfully use data-driven insights to drive positive changes in the organization. This will motivate others to adopt a similar approach.

By fostering a data-driven culture, organizations can unlock the full potential of their data, leading to improved decision-making, enhanced operational efficiency, and long-term success.

Implementing Data-Driven Strategies in Supply Chain and Manufacturing

To unlock success, organizations should apply data-driven strategic insights to their supply chain and manufacturing operations. Here are three example areas where data-driven strategies can make a significant impact:

- Demand Forecasting and Inventory Management: Accurate demand forecasting enables organizations to optimize inventory levels, reduce stockouts and overstock situations, and improve customer satisfaction. By leveraging data-driven insights, businesses can identify seasonal trends, promotional effects. And other factors influencing demand to create more accurate forecasts.

- Production Planning and Optimization: Data-driven production planning helps businesses optimize their manufacturing processes, reduce lead times, and increase overall efficiency. By analyzing data from production lines, machine performance, and workforce productivity, organizations can identify bottlenecks, reduce downtime, and optimize resource allocation.

- Supplier Performance Evaluation and Risk Management: Evaluating supplier performance and managing risks are critical components of a successful supply chain. Data-driven insights can help organizations monitor supplier performance metrics, such as lead times, quality, and reliability. That allows them to make informed decisions on supplier selection and risk mitigation.

Conclusion

Data-driven strategic insights are a powerful tool for supply chain and manufacturing organizations looking to optimize their operations. And to improve their decision-making, and stay ahead in a competitive marketplace. By understanding the importance of these insights, mastering the key components of data-driven decision-making, and fostering a data-driven culture, organizations can unlock the path to success.

Mastering the balance between reactive and proactive problem solving using data-driven insights is a journey. It requires continuous improvement, ongoing learning, and a commitment to leveraging data at every step. But the rewards—improved operational efficiency, reduced risk, and a competitive edge—are well worth the effort.

Remember, data is more than just numbers on a screen—it’s the key to unlocking your organization’s full potential. So start your data-driven journey today and unlock success with data-driven strategic insights!