Contents

TL;DR

- This post is about building a sustainable supply chain.

- In supply chain and green logistics, sustainability involves implementing environmentally-friendly practices to improve its environmental footprint.

- There is an economic basis for creating a sustainable supply chain.

- Essential practices include eco-friendly packaging, green transportation, and waste reduction.

- IKEA, Unilever, and BHP are implementing green supply chain initiatives.

As the world tussles with the mounting strain of climate change, businesses across all sectors recognize the need to reduce their environmental footprints. This urgency is manifesting powerfully within supply chains and logistics, with “green logistics” becoming an essential aspect of business strategies.

Introduction to Sustainable Supply Chain and Green Logistics

Understanding Sustainability in Supply Chain

The concept of a sustainable supply chain goes beyond mere compliance with environmental regulations. It represents a sweeping process of managing the environmental impact of each stage in a product’s lifecycle, from sourcing raw materials to manufacturing, transportation, and finally, the delivery of the finished product to the consumer.

Sustainable supply chain practices aim to minimize greenhouse gas emissions, conserve natural resources, reduce waste, and promote social equity. But the benefits of adopting such practices extend beyond environmental stewardship. Businesses implementing sustainability principles often experience increased operational efficiency, cost savings, improved risk management, and enhanced brand reputation.

The Role of Green Logistics

Green logistics encompasses all activities to minimize the ecological impacts of logistics functions. It includes developing and enforcing environmental policies, reducing energy consumption, adopting renewable energy sources, improving transportation efficiency, and promoting the reuse and recycling of materials.

Fundamentally, green logistics looks at how goods and materials move from one place to another. It assesses the carbon footprint of these movements and looks for ways to reduce it. Either by optimizing delivery routes to reduce fuel consumption, shifting to electric vehicles, or using energy-efficient warehousing techniques, every facet of a company’s logistics operations can contribute to its overall environmental footprint.

Economic Rationale for a Sustainable Supply Chain

Businesses are increasingly accepting that sustainability is not only ethically responsible but also economically beneficial. Here’s why:

- Cost Savings: Implementing sustainable practices often leads to cost savings in the long run. Efficient resource use, reduced waste, and optimized operations cut unnecessary expenses. For example, energy-efficient equipment may require an upfront investment but save money in reduced energy costs over time.

- Risk Mitigation: A sustainable supply chain helps mitigate risks, such as regulatory fines or reputational damage due to environmental incidents. Furthermore, with increasing climate change concerns, businesses face a risk of resource scarcity. A sustainable supply chain is better prepared to deal with such disruptions.

- Customer and Investor Appeal: Today’s consumers and investors are increasingly valuing sustainability. Companies with green practices attract customers willing to pay a premium for sustainable products. Similarly, demonstrating sustainability initiatives can attract investors, which signifies forward-thinking and responsible management. A 2022 report by Mckinsey shows that customers are focused on a brand’s sustainability efforts

- Competitive Advantage: Lastly, a sustainable supply chain can provide a significant competitive advantage. As sustainability becomes an expectation rather than an exception, companies leading the green revolution stand to gain the most.

Transparency and Traceability in Green Logistics

Transparency and traceability are essential to sustainable supply chains and green logistics. Consumers are increasingly aware of the environmental impact of their buying choices and demand access to information about their products. I’ve asked myself recently questions similar to the below and I wish I could make data driven decisions:

- Is this product designed to last or is it just a consumable?

- What is the actual footprint of this product?

- Did the T-shirt factory dump excess dye into a local waterway?

- Was my “eco” product shipped halfway across the world?

- For the same money, can I buy greener products?

Embedded Energy

Embedded energy is the sum of all the energy used to produce a product, from sourcing raw materials to manufacturing, transportation, and disposal. It’s a vital factor in assessing a product’s total environmental impact. Companies use data analytics to estimate the embedded energy of their products and share this information with customers, providing a fuller picture of a product’s environmental footprint.

Blockchain and Traceability

Blockchain technology, most known for underpinning cryptocurrencies like Bitcoin, has the potential to revolutionize supply chain transparency. With blockchain, companies can create a decentralized and immutable ledger of transactions, allowing for unparalleled traceability. Every step in a product’s lifecycle can be recorded and verified, from extraction of raw materials, through manufacturing processes, to delivery to the end consumer. Sustainability traceability might not have many applications in the current environment other than for particularly fastidious customers, however in the future, if there are legislations, fines, and carbon taxes tied to a company’s sustainability (or lack thereof), then businesses might wish to consider using a more transparent technology.

Empowering the Customer

By providing transparency and traceability, businesses can empower their customers to make more sustainable choices. Imagine having the information you need to make an informed decision when buying a product. You can then look for products that meet your expectations and values. This, in turn, incentivizes businesses to invest more in sustainable practices.

Implementing Sustainable Practices

Sustainable supply chain and logistics practices encompass various strategies and techniques. Mckinsey suggests that 7 of the nine most common ESG (environmental, social, and governance) initiatives have supply chain components, some examples below

Eco-Friendly Packaging

Packaging is integral to any product and contributes significantly to environmental degradation. Traditional packaging materials, such as plastic and Styrofoam, are notorious for their harmful environmental impact. These materials take hundreds of years to decompose, and their production processes often release harmful emissions.

Eco-friendly packaging offers an effective solution to these challenges. By replacing harmful materials with those that are biodegradable, recyclable, or derived from renewable resources, companies can significantly reduce the environmental impact of their operations. In addition, intelligent design techniques can minimize the amount of packaging needed without compromising the protection of the product.

Green Transportation

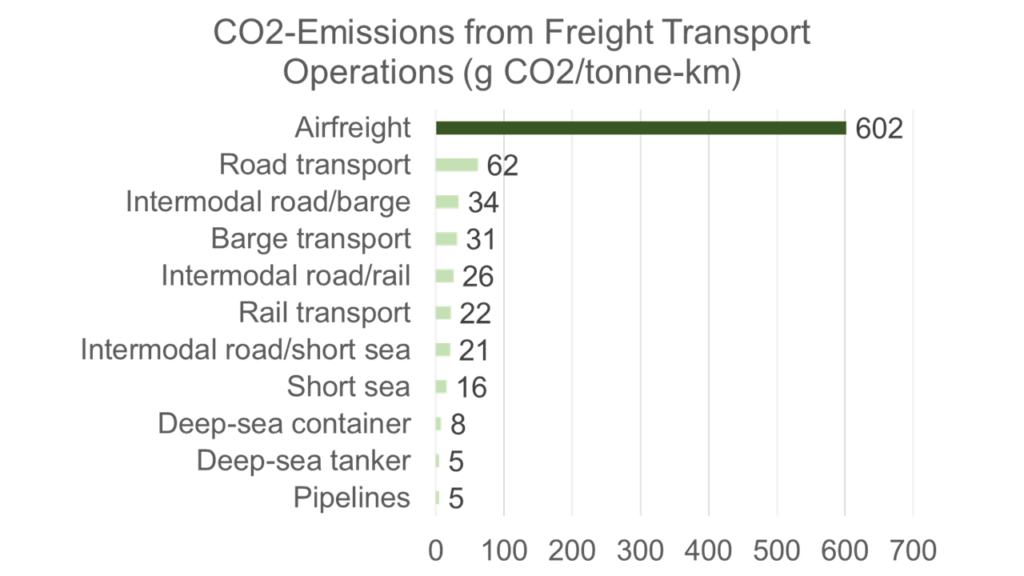

Green transportation involves using fuel-efficient vehicles, optimizing delivery routes to reduce mileage, and shifting towards cleaner modes of transport. With advancements in technology, companies have options to use electric or hybrid vehicles for deliveries, and software can optimize routes to minimize fuel consumption. With a more efficient supply chain or by holding more stock in critical locations, supply chain managers can often select more efficient modes of transport.

For example, the business is supplying a vital customer via air freight. A newly implemented forecasting model proves it can more accurately predict when a supply planner should place an order. This improvement means the supply chain can be more relaxed, and the supply chain manager recognizes that they can meet their green goals set by leadership (and the shareholders vicariously) by switching to road freight with a longer lead time.

Waste Reduction

Another crucial element of sustainable supply chain management is waste reduction. This involves eliminating unnecessary elements from the production process, increasing resource use efficiency, and finding ways to reuse or recycle waste materials.

Supply chain managers can achieve this by implementing strategies such as lean manufacturing, which aims to eliminate waste in all forms, and closed-loop supply chains, where waste materials are recycled back into the production process. In many cases focusing on lean manufacturing principles can lead to cost reductions and improved output.

Many companies implement continuous improvement project management methodologies such as Lean 6 Sigma.

Case Studies: Successful Green Supply Chain Initiatives

Several companies have managed to implement or are in the process of implementing green supply chain initiatives:

- IKEA, the Swedish furniture retailer, has implemented several different initiatives, “IWAY,” a supplier sustainability code of conduct. An annual sustainability report and inventory management practices to reduce waste

- Similarly, Unilever, the multinational consumer goods company, has pledged to replace virgin plastics with 25% post-consumer recyclables compostable by 2025. (at the end of 2020 was sitting at a 10% footprint

- BHP, the resource company, is implementing initiatives; for example, by 2030, have committed to having at least 30% of its land and water under conservation.

Even if some companies are attempting to greenwash (I can’t/won’t guess at who), it’s not relevant as what this shows is that there is an underlying market pressure to be more sustainable, demonstrating that a commitment to sustainability can be both environmentally responsible and economically viable.

Conclusion: The Future of Sustainability in Supply Chain

As the implications of climate change become increasingly apparent, the importance of sustainable supply chains and green logistics can only grow. Embracing sustainability is a matter of environmental responsibility and a strategic imperative that can drive efficiencies, reduce costs, and enhance corporate reputations. The time to act is now – for the planet, the people, and the bottom line.